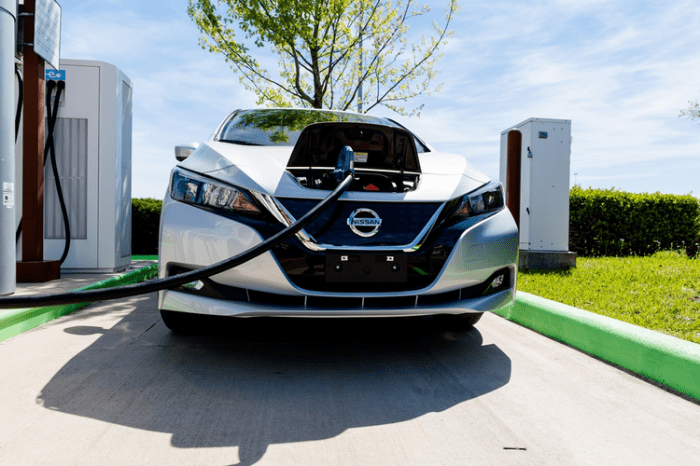

Nissan reuse EV batteries camping trailers – sounds crazy, right? But picture this: ditching noisy generators and embracing sustainable off-grid adventures powered by repurposed electric vehicle batteries. This isn’t just a pipe dream; it’s a clever way to give EV batteries a second life while powering your eco-friendly camping escapades. We’ll dive into the practicalities, from adapting the batteries to designing your trailer for optimal power and safety.

This guide explores the technical aspects of converting used Nissan EV batteries into a reliable power source for your camping trailer. We’ll cover everything from battery characteristics and safety considerations to system design, thermal management, and a comprehensive power consumption analysis. We’ll also look at the environmental and economic benefits of this innovative approach, highlighting the potential for cost savings and reduced environmental impact compared to traditional power sources.

Adapting Nissan EV Batteries for Camping Trailer Power Systems: Nissan Reuse Ev Batteries Camping Trailers

Repurposing Nissan EV batteries for off-grid power in camping trailers presents a compelling opportunity for sustainable and powerful energy solutions. This approach leverages the high energy density of these batteries, offering a significant advantage over traditional lead-acid systems. However, careful consideration of safety, conversion, and thermal management is crucial for a successful implementation. This section details the design and integration of a Nissan EV battery pack into a camping trailer power system.

Power Conversion System Design

A safe and efficient power conversion system is essential for utilizing Nissan EV battery packs. The system needs to handle the high voltage (typically 300-400V) of the battery pack and convert it to the lower voltages required by typical camping trailer appliances (12V and 24V). This involves a multi-stage process. First, a high-voltage DC-DC converter steps down the battery pack voltage to an intermediate voltage, perhaps 48V. This intermediate voltage then feeds into separate DC-DC converters for 12V and 24V outputs. These converters should incorporate appropriate protection mechanisms, including over-current, over-voltage, and short-circuit protection. A simplified schematic might show the Nissan EV battery pack connected to a high-voltage DC-DC converter, which then branches to two lower-voltage DC-DC converters, each feeding a separate 12V and 24V busbar. These busbars then distribute power to the trailer’s appliances. The entire system needs robust fusing and circuit breakers for safety. Consideration should also be given to the use of a battery monitoring system which constantly measures voltage, current, and temperature to prevent overcharging, under-charging and overheating.

Bill of Materials for 12V and 24V Power Systems

The following tables Artikel the components required for building a 12V and 24V power system using repurposed Nissan Leaf battery modules. Note that these are estimates and the specific components may vary based on the chosen battery modules and desired power output. The cost estimates are also approximations and can change significantly depending on sourcing.

12V System Bill of Materials

| Component | Quantity | Estimated Cost (USD) |

|---|---|---|

| Nissan Leaf Battery Modules (Used) | 2-3 (depending on desired capacity) | $500 – $1500 |

| 48V to 12V DC-DC Converter | 1 | $100 – $300 |

| 12V Fuse Block | 1 | $20 – $50 |

| Wiring and Connectors | As needed | $50 – $100 |

| Battery Management System (BMS) | 1 | $200 – $500 |

| Enclosures and Mounting Hardware | As needed | $50 – $100 |

24V System Bill of Materials

| Component | Quantity | Estimated Cost (USD) |

|---|---|---|

| Nissan Leaf Battery Modules (Used) | 4-6 (depending on desired capacity) | $1000 – $3000 |

| 48V to 24V DC-DC Converter | 1 | $150 – $400 |

| 24V Fuse Block | 1 | $30 – $75 |

| Wiring and Connectors | As needed | $75 – $150 |

| Battery Management System (BMS) | 1 | $300 – $700 |

| Enclosures and Mounting Hardware | As needed | $75 – $150 |

Battery Management System (BMS) Integration

A BMS is crucial for safe and efficient operation of the repurposed Nissan EV battery pack. The BMS monitors individual cell voltages, current, temperature, and state of charge (SOC). It prevents overcharging, over-discharging, over-current, and short circuits. Integration involves connecting the BMS to the battery pack and the power conversion system. The BMS communicates with the DC-DC converters, providing real-time data and controlling charging and discharging to optimize battery life and safety. A proper connection diagram showing the BMS interfacing with each cell within the battery pack, the high-voltage DC-DC converter, and potentially a user interface for monitoring is essential. This connection diagram should clearly illustrate the communication protocols used between the BMS and other system components.

Thermal Management of Nissan EV Batteries

Maintaining optimal operating temperatures for the Nissan EV battery pack is critical for performance and longevity. Extreme temperatures can degrade battery performance and reduce its lifespan. In a camping trailer environment, this is particularly important as temperatures can fluctuate significantly. Strategies for thermal management include: insulation to minimize heat loss in cold weather, ventilation to dissipate heat in warm weather, and potentially active cooling systems like fans or thermoelectric coolers for extreme conditions.

| Temperature Range (°C) | Mitigation Strategy |

|---|---|

| Below -20 | Insulation, pre-heating (if feasible) |

| -20 to 10 | Insulation |

| 10 to 30 | Passive ventilation |

| 30 to 40 | Active ventilation (fans) |

| Above 40 | Active cooling (thermoelectric cooler), potential shutdown |

Camping Trailer Design Considerations for Nissan EV Battery Integration

Repurposing Nissan EV batteries for off-grid camping power is a compelling idea, but successfully integrating these hefty power packs into a camping trailer requires careful planning and design. The weight, size, and inherent safety concerns of these batteries demand a robust and well-thought-out approach. Ignoring these considerations could lead to structural failure, electrical hazards, or even injury.

Suitable Camping Trailer Designs

The physical dimensions and weight of Nissan EV battery packs significantly influence the choice of camping trailer. A trailer’s structural integrity must be able to handle the added load without compromising safety or maneuverability. Selecting a trailer with a robust chassis and sufficient ground clearance is crucial.

- Heavy-duty teardrop trailers: Their compact design and sturdy construction offer a good starting point, though modifications will likely be necessary.

- Custom-built trailers: This provides the most flexibility to optimize the design around the battery pack’s dimensions and weight.

- Larger, off-road capable trailers: These trailers typically have stronger frames and suspensions better suited for carrying heavier loads.

Structural Reinforcement for EV Battery Weight

The weight of a Nissan LEAF battery pack, for instance, can exceed 300kg. This significant added weight necessitates substantial structural reinforcement of the trailer frame and suspension. Without proper reinforcement, the trailer risks bending, cracking, or even catastrophic failure, particularly during off-road use.

Reinforcement strategies could include adding extra cross-members to the chassis, upgrading the suspension components (e.g., heavier-duty axles, shocks, and springs), and potentially reinforcing the trailer tongue. The specific reinforcement needed depends on the battery pack’s weight and the trailer’s existing construction. Professional engineering consultation is highly recommended for this critical aspect.

Optimal Placement of EV Batteries

Strategic placement of the battery pack is crucial for maintaining the trailer’s stability and center of gravity. Ideally, the batteries should be positioned as low and centrally as possible to minimize sway and improve handling.

Placing the batteries near the trailer’s axle(s) is generally a good strategy for weight distribution. Accessibility for maintenance and connection to the power system is another key consideration. A dedicated compartment with secure locking mechanisms is essential to prevent damage and unauthorized access.

Safety Features for Repurposed EV Batteries

Integrating repurposed EV batteries into a camping trailer demands a comprehensive approach to safety. The risks associated with high-voltage systems require careful mitigation.

- Battery Management System (BMS) integration: A properly functioning BMS is critical for monitoring battery voltage, current, temperature, and state of charge, preventing overcharging, over-discharging, and thermal runaway.

- High-voltage disconnect switch: A readily accessible switch should allow for immediate disconnection of the battery pack in case of emergency.

- Adequate ventilation: Proper ventilation is crucial to dissipate heat generated by the batteries, preventing overheating and potential fire hazards. This might involve dedicated vents or even a cooling system.

- Fire suppression system: A fire suppression system, such as a fire extinguisher specifically rated for lithium-ion battery fires, should be installed within easy reach.

- Insulation and protection: The batteries should be housed in a robust, impact-resistant, and insulated enclosure to protect them from physical damage and the elements.

Power Consumption Analysis for a Camping Trailer with Nissan EV Batteries

Repurposing Nissan EV batteries for off-grid camping trailers offers a compelling alternative to traditional power sources. However, understanding the energy demands of typical camping appliances and optimizing their usage is crucial for maximizing battery life and ensuring a successful off-grid experience. This analysis delves into the power consumption aspects of such a setup, offering insights into energy efficiency and usage optimization.

Typical Appliance Energy Consumption in a Camping Trailer

Understanding the energy consumption of various appliances is the first step in planning your off-grid power system. The following table provides estimates for common camping appliances, assuming average usage patterns. Note that actual consumption can vary depending on the specific appliance model and usage.

| Appliance | Power Consumption (Watts) | Daily Usage (hours) | Total Daily Energy Consumption (Wh) |

|---|---|---|---|

| LED Lighting (interior) | 50 | 6 | 300 |

| Refrigerator (12V) | 50 | 24 | 1200 |

| Laptop/Tablet | 40 | 3 | 120 |

| Water Pump (12V) | 100 | 1 | 100 |

| Phone Charging | 10 | 2 | 20 |

| Induction Cooktop (high power) | 1500 | 1 | 1500 |

Estimated Runtime with Repurposed Nissan EV Batteries

A typical Nissan Leaf battery pack has a usable capacity of around 40 kWh. Considering the daily energy consumption from the table above (excluding the induction cooktop, which is used intermittently), we have a total daily consumption of approximately 1740 Wh. This means the battery could theoretically power the trailer for over 22 days (40,000 Wh / 1740 Wh ≈ 23 days). However, this is a best-case scenario. In reality, factors like battery degradation and inefficiencies in the power conversion system will reduce this runtime. For example, if we include an hour of induction cooktop use daily, the runtime significantly drops.

Energy Efficiency Comparison: Nissan EV Batteries vs. Other Sources, Nissan reuse ev batteries camping trailers

Compared to propane, Nissan EV batteries offer a cleaner and potentially more efficient power source, particularly for consistent low-power demands like lighting and refrigeration. Propane appliances can be less energy-efficient, and propane itself requires transportation and storage. Gasoline generators, while capable of high power output, are noisy, pollute the environment, and consume significant fuel. The energy efficiency of the Nissan EV battery system depends heavily on the inverter’s efficiency and the overall design of the power system. However, for moderate usage, it offers a quieter and cleaner alternative to both propane and gasoline generators.

Optimizing Energy Consumption to Maximize Battery Lifespan

Maximizing the lifespan of your repurposed Nissan EV batteries requires a mindful approach to energy consumption. This includes:

- Using energy-efficient appliances: Opt for LED lighting, low-power refrigerators, and efficient electronics.

- Minimizing high-power appliance use: Limit the use of appliances with high power consumption, like induction cooktops, to short durations.

- Smart energy management: Employ a battery management system (BMS) to monitor battery levels and prevent over-discharge.

- Strategic appliance scheduling: Avoid running multiple high-power appliances simultaneously.

- Regular battery maintenance: Follow the manufacturer’s guidelines for battery maintenance to extend its lifespan.

Repurposing Nissan EV batteries for camping trailers offers a compelling blend of sustainability and practicality. By carefully considering design, safety, and power management, you can create a truly off-grid adventure, powered by a second-life battery system that’s both environmentally friendly and cost-effective. It’s a win-win – for your wallet and the planet. So, ditch the gas guzzlers and embrace the quiet hum of sustainable adventure!

Informatif Berita Informatif Terbaru

Informatif Berita Informatif Terbaru